In today’s environmentally conscious world, businesses are increasingly recognizing the importance of sustainable practices in their operations. This extends to warehouse management, where adopting eco-friendly strategies can significantly reduce environmental impact. In this blog post, we will explore six best practices for creating a sustainable warehouse that minimises waste, reduces energy consumption, and promotes a greener logistics framework. By implementing these practices, businesses can optimise their operations while contributing to a more sustainable future.

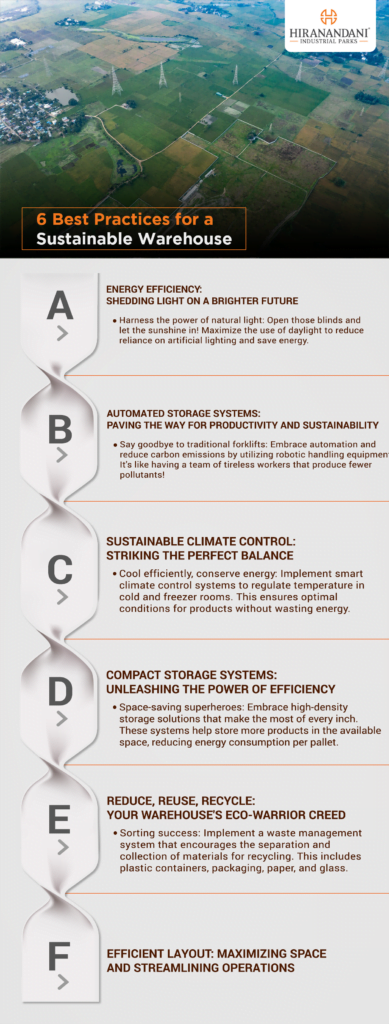

Energy Efficiency: Illuminating the Path to Sustainability

To maximise energy efficiency, organisations can take advantage of natural light and use energy-efficient lighting. Some popular resources are skylights, solar panels, and sensors. Energy management systems can also be implemented to make effective use of power. For instance, machines can be shut down when they’re not being operated. With these solutions, businesses can reduce their dependence on fossil fuels as well as their carbon emissions.

Automated Storage Systems: Combining Productivity and Sustainability

Automation is a rising trend. According to the 2021 MHI Annual Industry Report, as a result of the coronavirus pandemic, 43% of businesses surveyed claim to have spent $5-10 million on robotics and automation, while 53% say they plan to substantially increase their investment in this area.

So, why is automation associated with sustainability? Because automatic handling equipment emits fewer polluting gases and helps to lessen the traffic of traditional forklifts with internal combustion engines. Meanwhile, automated facilities can operate in lights-out mode as dark warehouses, thus reducing their carbon footprint.

Sustainable Climate Control: Striking the Right Balance

Air conditioning entails high energy consumption, especially in cold and freezer rooms. The aim is to store these products in the right conditions while minimising energy consumption.

When it comes to efficient climate control in a facility, the difficulty lies in its structure. As a general rule, warehouses are large industrial buildings with high ceilings and multiple openings to the outside, where the cold air from the street seeps in. How can this be mitigated? One option is to build warehouses with insulating materials such as sandwich panels, which prevent the transfer of the temperature to the outside.

Compact Storage Systems: Optimising Space and Energy Consumption

High-density storage systems can contribute towards achieving a sustainable warehouse design. These storage solutions leverage the available surface area to house a larger number of products. In rooms with controlled temperatures, compact solutions reduce the energy consumption per pallet stored.

High-density systems comprise various solutions with particular functions and characteristics: drive-in drive-thru pallet racks, pallet flow racks, push back racks, and the Pallet Shuttle system. The choice of one solution or another will depend on factors such as the available space or number of flows required.

Reduce, Reuse, Recycle: Minimizing Waste and Promoting Circular Economy

The US Environmental Protection Agency estimated 14.5 million tons of plastic containers and packaging were generated in 2018, approximately 5.0 percent of municipal solid waste (MSW). Taking into account that logistics activities generate a lot of waste, in eco-friendly warehouses, the materials used on a day-to-day basis in the facility are collected separately.

Society is becoming more and more aware of the importance of recycling. The total volume of plastic containers and packaging MSW recycled in the US was 1.98 million tons in 2018, according to the EPA. In sustainable warehouses, recycling the different types of packaging is increasingly common.

Likewise, other waste, such as paper and glass, can be produced in a logistics facility. Separating, recycling, and reusing them can help to minimise the environmental impact of logistics.

Efficient Layout: Maximizing Space and Streamlining Operations

Making the most of the warehouse storage systems is essential for maximising the throughput of the various operations taking place in the warehouse. To accomplish this, the first step is to optimise the warehouse layout and install the storage system that best meets the business’s needs.

Although this process can be carried out in different ways, one of the most effective is to employ warehouse simulation software. This creates a virtual representation of a logistics facility that allows companies to run a number of tests to analyse the maximum performance of the warehouse in situations such as an increase in order volumes.

Warehouse for a Sustainable Future

Environmental concerns are the order of the day. Organisations can have sustainable warehouses by optimising all operations in their supply chain. With efficient processes, companies can provide good service with minimal environmental impact.

Hiranandani Industrial Parks (HIP) is committed to creating sustainable warehouses and has implemented a range of initiatives that align with the best practices for sustainability. These initiatives include:

HIP has utilised SRI sheets, a special white paint that reflects sunlight, reducing the need for cooling and resulting in electricity savings. By incorporating transparent sheets on the roof, natural light is maximised, reducing the requirement for artificial lighting. Additionally, HIP has implemented a roof monitor system that removes hot air and replaces it with fresh cool air, reducing electricity consumption.

To create a greener environment, HIP follows guidelines from the Indian Green Building Council (IGBC) for the area covered by plants and trees. Energy efficiency is a priority for HIP, and they adhere to IGBC guidelines for reduced diesel consumption and overall energy optimization. Energy-efficient LED lighting fixtures are installed throughout the infrastructure to conserve energy, and energy-efficient pumps, such as the IE3 pump, are used to minimise energy consumption. Solar panels with a capacity of 10 kilowatts per box are incorporated to harness renewable energy, further reducing dependence on traditional energy sources.

HIP focuses on water conservation through initiatives like rainwater harvesting pits, which collect and utilise rainwater to recharge groundwater. Water-saving plumbing fixtures are installed to reduce water consumption, and sewage treatment plants (STPs) are implemented to treat wastewater and minimise environmental impact.

To promote proper waste management and recycling, HIP provides separate colour-coded dustbins for different types of waste. They also prioritise the use of environmentally friendly products that meet green standards, such as Ultratech coded products.

Furthermore, HIP ensures the well-being of staff and drivers by providing basic facilities, including first aid, water, and other essential amenities. By implementing these sustainable initiatives, Hiranandani Industrial Parks demonstrates its commitment to creating warehouses that are not only efficient and productive but also environmentally responsible and aligned with best practices for sustainability.At Hiranandani Industrial Parks, we develop storage solutions adapted to the requirements of businesses from all sectors. Be sure to get in touch — our solutions will help you optimise your operations.