Table of Contents

ToggleVertical Warehouses for 3PL Providers in Chennai

Vertical warehouses are multi-level storage facilities designed to maximize limited space, especially in urban areas like Chennai. With the rise of 3PL (third-party logistics) providers, the demand for space-efficient solutions has surged. Vertical warehouses offer the ability to store more goods within a smaller footprint, solving space constraints while supporting the growing logistics industry.

Source: Knight Frank India

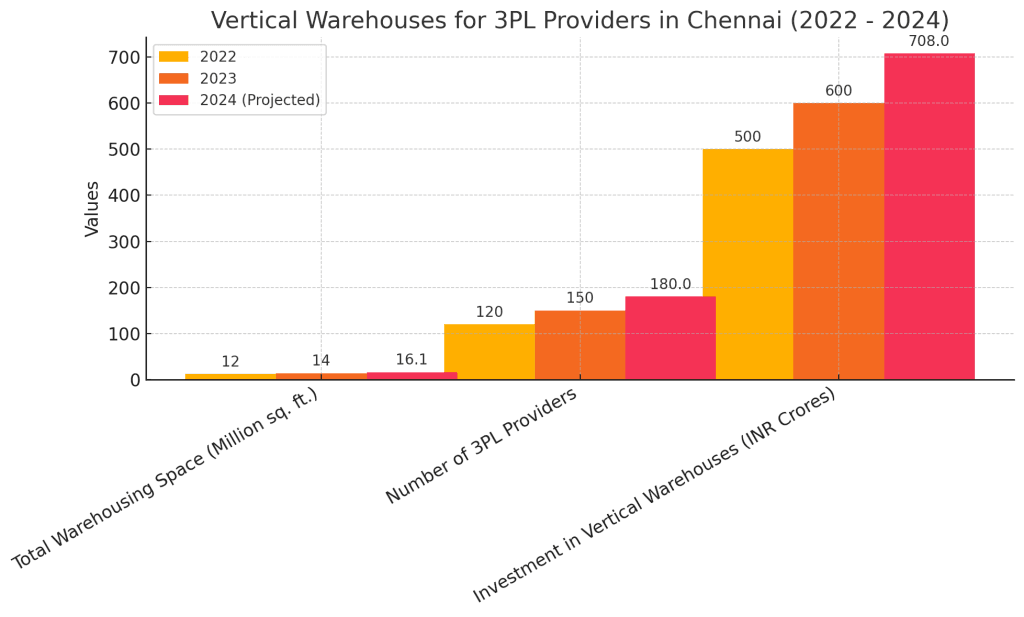

Based on these projections, we expect further expansion in the vertical warehousing sector in Chennai, driven by the growing demands of 3PL providers and increased investment in infrastructure.

Structural Design Considerations for Multi-Level Storage

When developing vertical warehouses, key design aspects such as load-bearing capacity and efficient floor plans come into play. Developers often incorporate mezzanine levels and optimize vertical space for better storage density. This is critical for 3PL providers managing varied inventory profiles, from lightweight consumer goods to heavy industrial materials.

Recent reports project a 10-12% CAGR for India’s warehousing industry over the next five years. Chennai, a key logistics hub, has seen a 20% rise in vertical warehouse adoption due to limited land availability. In 2023, 3PL providers occupied over 35% of the region’s warehousing space.

Integrating Automation in Vertical Warehouse Setups

To fully capitalize on vertical space, automation is crucial. Technologies such as Automated Storage and Retrieval Systems (AS/RS), conveyor belts, and vertical lifts streamline the movement of goods across floors. Additionally, robotic picking systems paired with Warehouse Management Systems (WMS) allow for faster and more accurate order fulfillment, while IoT devices provide real-time tracking of inventory.

Automation in vertical warehouse setups involves systems such as automated storage and retrieval systems (ASRS), robotics, and conveyor systems. Maintenance costs have shown an annual growth of around 5-7% due to the increasing complexity of automated systems and the need for specialized technicians to ensure smooth operations. Despite these costs, the investment results in significant long-term savings in labor expenses and enhanced operational efficiency.

Safety Standards and Building Codes for Vertical Facilities

Building vertical warehouses requires adherence to strict safety standards, especially in India. From fire safety measures to structural integrity and seismic resistance, compliance with local building codes is essential. Environmental sustainability also plays a role, with green certifications becoming more relevant in warehouse design.

Major safety standards for vertical facilities include fire-resistant materials, adherence to fire safety codes (such as NFPA 5000), proper emergency exits, automated fire suppression systems, seismic resistance for earthquake-prone areas, load-bearing capacity standards, and compliance with Occupational Safety and Health Administration (OSHA) regulations for safe worker environments.

Space Optimization Techniques for 3PL Vertical Warehouses

Maximizing space is a key concern in vertical warehouses. Implementing narrow aisle racking systems, double-deep racking, and mobile shelving solutions helps increase storage density. Well-designed loading and unloading zones ensure that goods flow smoothly in and out of the facility.

Cutting-Edge Technologies for Vertical Warehouse Management

The use of emerging technologies like artificial intelligence (AI) for predictive inventory management, augmented reality (AR) for picking and staff training, and blockchain for supply chain transparency enhances vertical warehouse efficiency. Cloud-based systems provide real-time access to data, further optimizing decision-making.

Here’s a table highlighting the importance of cutting-edge technologies for vertical warehouse management:

Future Trends in Vertical Warehousing for 3PL Providers

Looking ahead, we expect the integration of drone technology for faster inventory checks and deliveries, 5G-enabled connectivity for seamless data sharing, and sustainable design practices that reduce the environmental footprint of vertical warehouses. These trends will drive further innovation in the 3PL industry in Chennai.

The Future of Vertical Warehouses for 3PL Providers in Chennai

Source : AmazonNews

Here is the projection graph for vertical warehouses for 3PL providers in Chennai, showing the comparison between 2022, 2023, and the projected values for 2024. The expected growth across key parameters, such as warehousing space, the number of 3PL providers, and investment in vertical warehouses, indicates strong future trends in the sector.

Vertical warehouses offer a promising solution to space constraints for 3PL providers in Chennai. By combining innovative design, automation, and cutting-edge technologies, these facilities can significantly boost operational efficiency. As Chennai’s logistics sector continues to expand, investing in future-proof warehouse designs will be critical for 3PL companies seeking to stay ahead of the curve.